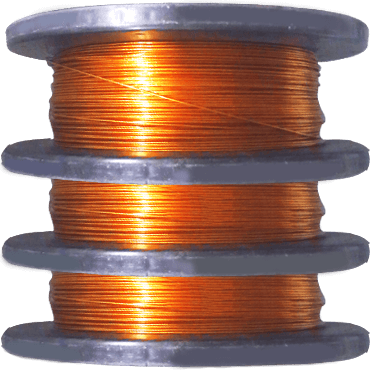

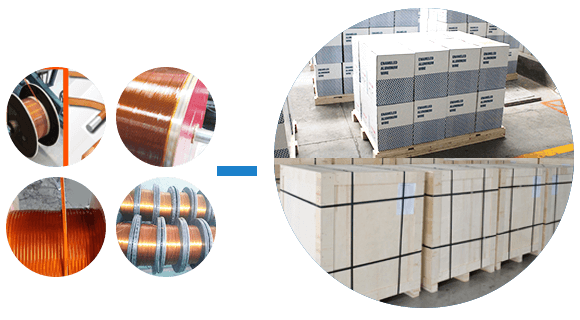

Kapton Copper Magnet Wire

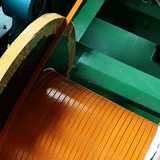

- DiameterRange (mm): Round:1.5-4.0mm Flat:a:1-5.6mm b: 3-16mm

- Temperature Class (C): 240

- Standard: UL,SGS,ROHS,ISO

- Package: 50kg/100kg/150kg wooden spool

We're here to help:Easy ways to get the answers you need.

We're here to help:Easy ways to get the answers you need.

Kapton Copper Magnet Wire

.png)

Size: round:1.5-4.0mm

flat: a:1.0-5.6mm b:3-16mm

Thermal Class:240

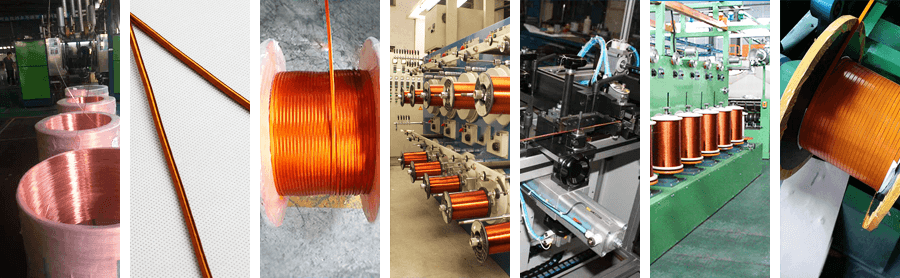

Production Characteristics

.png)

1. Our Kapton Copper Wire's machine is high-tech machine.

2. Our Kapton Copper Wire adopts high-quality F46 Polyesterimide layer and finishs through high heat sintering.

.png)

3. Our Kapton Copper Wire’s temperature can reach 290℃ and its voltage class can be 7200v.

4. Our Kapton Copper Wire has good quality, good mechanical strength and excellent chemical resistance.

5. Our Kapton Copper Wire can be used in serious environment of motors.

.png)

| Item | Requirement of the standards |

| Stardards |

GB/T7095.3 |

| Electrical resistivity | ≤0.017241Ω mm²/m |

| Breakdown voltage | 7200V |

| Heat shock | The minimum Heat shock temperature 175℃ |

| Resistance to solvents | Standard solvent.Use a pencil of hardness”2H”the coating shall not be removed |

| Cut Through | 320℃, 2mins not break down |

Please fill in your procurement needs and contact information