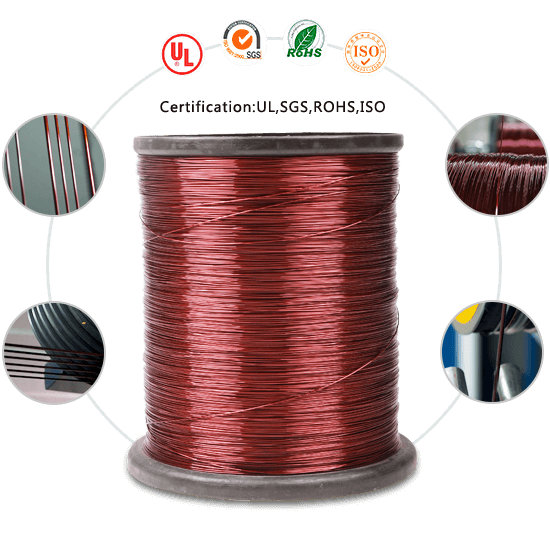

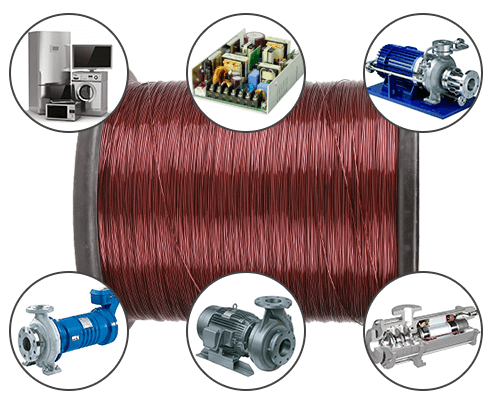

Enameled Copper Clad Aluminum Wire

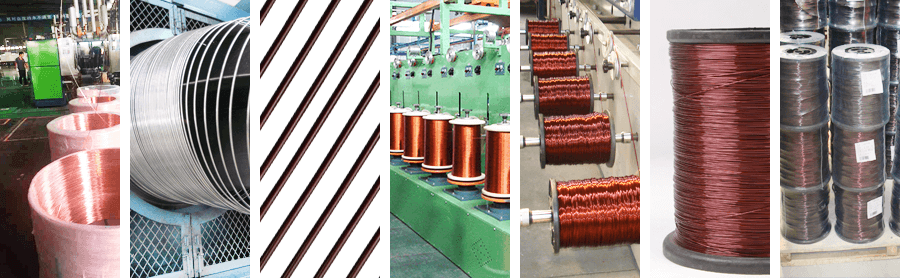

- DiameterRange (mm): 0.19-4.0mm

- Temperature Class (C): 130, 155, 180, 200, 220

- Standard: IEC, NEMA, GB, JIS

- Color: natural color, red, blue, green and so on

- Package: PT-25,PT-30,PT-60,30kg/50kg wooden spool or according to cumtomer requirement

We're here to help:Easy ways to get the answers you need.

.jpg)

.jpg)

.jpg)